Assignment:

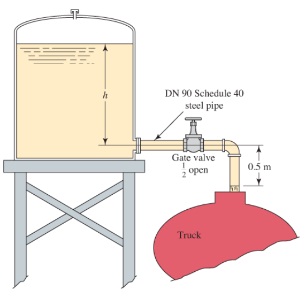

1. The figure below depicts gasoline flowing from a storage tank into a truck for transport. The gasoline has a specific gravity of 0.68 and the temperature is 25°C. It can be proved that for depth h of 3.20 in in the tank, the flow into the truck is of 1500 L/min. For that, because the pipes are short, the energy losses due to pipe friction were neglected, but minor losses were certainly considered.

a. The total pipe length is 1 m. Compute the pipe friction loses to prove that indeed for this problem the pipe friction losses could be neglected.

b. For the same depth h, what would be the flow rate if the gate valve is fully open? Again, assume pipe friction losses to be negligible.

c. For the same depth h, what would be the gate valve K value if the required flow rate is 1,000 IJmin? Again, assume pipe friction losses to be negligible.

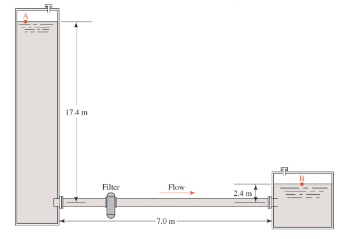

2. The figure below shows a part of a chemical processing system in which propyl alcohol at 25°C is taken from the bottom of a large tank and transferred by gravity to another part of the system. The length between the two tanks is 7.0 m. A filter is installed in the line and is known to have a resistance coefficient K of 8.5 based on the pipe velocity head. It can be proved that for a 32mm OD stainless steel tubing with 2mm wall thickness (see Appendix G.2 of our book) the flow rate is 160.98 L/min.

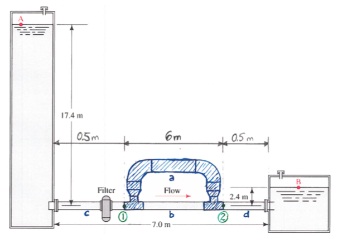

You, as the new engineer in the company, are asked to redesign the system to increase the flow rate to 180 L/min. For that you were suggested to put a parallel pipe "a" as shown in the figure. The total new pipe length is 6.1 m. Specify the standard size of tubing from Appendix G.2 for the new parallel tubing that would give a total volume flow rate of 180 L/min.

For the minor losses, use the following coefficients for each of the fittings: expansion K=0.7, reduction K=0.2, elbow K=0.22, tee-branch 1CD.65, tee-run K=0.22, entrance to pipe K=0.78, exit of pipe K=1.0

NOTE: Assume the pipe friction factor depends only on pipe relative roughness.