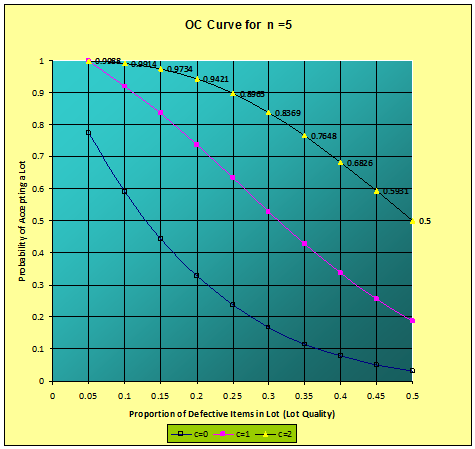

Q1: In a single sampling plan the sample size n =5. The submitted lot has on an average 25% defective items. Three acceptance numbers ( c = 0, c =1, and c=2) are being negotiated between the manufacturer and the buyer. Which acceptance number is most desirable from the manufacturer's viewpoint. You may use the following OC curve to find the answer.

a) c = 0

b) c = 1

c) c = 2

Q 2: In a double sampling plan the two acceptance numbers are: c1 = 8 and c2 = 12. The number of defectives found in the first sample is 9. Therefore, a second sample is taken. What is the maximum number of defectives allowed in the second sample for the lot to be accepted?

a) 0

b) 1

c) 2

d) 3

e) 4

Twenty samples of n = 200 were taken by an operator at a workstation in a production process. The number of defective items in each sample was recorded as follows. Answer

Q 3.

Number Number

Sample of Defectives Sample of Defectives

1 12 11 16

2 18 12 15

3 10 13 13

4 15 14 16

5 16 15 18

6 19 16 17

7 17 17 18

8 12 18 20

9 11 19 21

10 14 20 22

Management wants to develop a p-chart. The desired confidence level is 80.0 percent.

Q 3: What is the upper control limit?

Cans of soup are supposed to weigh exactly 16 oz. Inspectors want to develop process control charts. They take eight samples of five boxes and weigh them. They obtain the following data. Answer Q 4, and Q 5.

Sample Mean Range

1 15.2 1.8

2 14.6 0.7

3 16.5 0.5

4 18.1 0.4

5 13.2 0.2

6 16.0 0.4

7 15.9 0.5

8 14.8 0.9

Q 4: What is the upper control limit for the x-bar chart?

Q 5: What is the upper control limit for the R chart?

Cholesterol Palace is a fast-food restaurant. Management was concerned with errors in filling orders at its drive-up window. It hired several undercover quality inspectors to randomly place 100 orders while the process seemed to be in control. The completed orders were then checked for accuracy. The following table shows the results of the survey. Answer Q 6, Q 7, and Q 8.

Defect Frequency

Incomplete, shorted order 12

Unordered items dispensed 2

Wrong product dispensed 14

Wrong toppings 14

Wrong size drink 2

Drink lid not sealed 17

No drinking straw with soft drink order 0

No napkins 18

Far too many condiment packets 65

No salt with sandwich or fries order 10

Wrong change 3

Other 12

QC 6: Use these data to estimate the average number of defects per order.

QC 7: What is the lower control limit for a c-chart. Use z =3.

QC 8: A quality inspector just used the drive-up window and now checks her order. Her cheeseburger has mustard on it although she ordered it without ketchup or mustard. Three handfuls of ketchup and mustard packets are in the sack, but no napkins. And hot coffee has spilled because the lid wasn't properly sealed. Is the drive-up process in control?

PROBLEMS ON PROJECT MANAGEMENT

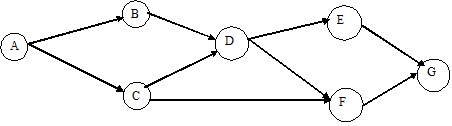

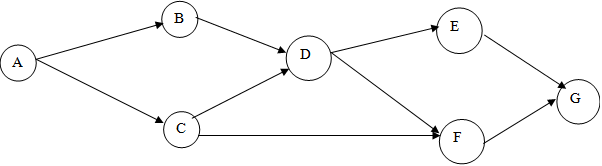

Q 9: Use the data given in the following table and the relationships between activities shown in the Activity on Node (AON) network. Find the project duration (earliest completion time of the project).

|

Activity

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

|

Time (days)

|

5

|

6

|

9

|

4

|

9

|

3

|

4

|

a) 21

b) 22

c) 25

d) 28

e) 31

Q 10: Use the data given in the following table and the relationships between activities shown in the Activity on Node (AON) network. What is the latest start time of activity C if the project completion time (due date) is set at 33 day?

|

Activity

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

|

Time (days)

|

5

|

6

|

9

|

4

|

9

|

3

|

4

|

a) 5

b) 7

c) 33

d) Zero (0)

You may use the following table.

|

Activity

|

Immediate Predecessor

|

Time

|

Late Start

|

Late Finish

|

|

A

|

|

|

|

|

|

B

|

|

|

|

|

|

C

|

|

|

|

|

|

D

|

|

|

|

|

|

E

|

|

|

|

|

|

F

|

|

|

|

|

|

G

|

|

|

|

33

|

Q 11: The data for a Time-Cost CPM Scheduling model analysis are given below. The times are in days. What is the minimum cost to complete this project in 14 days?

|

Activity

|

Immediate Predecessor

|

Normal Time

|

Crash Time

|

Normal Cost ($)

|

Crash Cost ($)

|

|

A

|

None

|

4

|

2

|

2000

|

4000

|

|

B

|

A

|

4

|

3

|

3000

|

6000

|

|

C

|

A

|

2

|

1

|

2000

|

2500

|

|

D

|

B and C

|

4

|

2

|

5000

|

5600

|

|

E

|

D

|

3

|

1

|

6000

|

9000

|

a) 18,000

b) 27,100

c) 18,300

d) 300

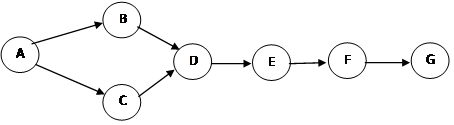

Q 12: You have collected the data for a Time-Cost CPM Scheduling model analysis. The time is in days and the project "direct costs" are given below.

|

Activity

|

Immediate Predecessor

|

Normal Time (days)

|

Crash Time (days)

|

Normal Cost (Direct) $

|

Crash Cost (Direct) $

|

|

A

|

None

|

3

|

2

|

300

|

400

|

|

B

|

A

|

3

|

3

|

100

|

100

|

|

C

|

A

|

1

|

1

|

200

|

200

|

|

D

|

B and C

|

3

|

2

|

400

|

550

|

|

E

|

D

|

2

|

1

|

500

|

900

|

|

F

|

E

|

3

|

3

|

200

|

200

|

|

G

|

F

|

2

|

2

|

100

|

100

|

The network for this project is given below.

The indirect costs for the project are determined on a daily duration basis and are given below:

Total indirect costs for 16 days of project duration: $ 600

Total indirect costs for 15 days of project duration: $ 400

Total indirect costs for 14 days of project duration: $ 200

Total indirect costs for 13 days of project duration: $ 100

At what project duration do we achieve the lowest total project cost (i.e., direct plus indirect costs)?

(a) 16 days

(b) 15 days

(c) 14 days

(d) 13 days

Consider a project having the following ten activities. Answer Q13 and Q14.

|

Activity

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

I

|

J

|

|

Immediate Predecessors

|

None

|

None

|

A

|

A,B

|

C,D

|

D

|

C

|

E,G

|

E,F

|

H,I

|

|

Time (weeks)

|

|

7

|

3

|

5

|

6

|

4

|

4

|

9

|

8

|

6

|

5

|

|

|

|

|

|

|

|

|

|

|

|

|

Q13: What is the critical path?

a) A-C-G-H-J

b) A-B-C-D-E-F-G-H-I-J

c) A-D-E-H-J

d) B-D-F-I-J

Q 14: What is the slack time of activity B?

a) zero

b) 8

c) 11

d) 3

e) 19

You may use the following table.

|

Activity

|

Immediate Predecessor

|

Time

|

Early Start

|

Early Finish

|

Late Start

|

Late Finish

|

Slack Time

|

|

A

|

|

|

|

|

|

|

|

|

B

|

|

|

|

|

|

|

|

|

C

|

|

|

|

|

|

|

|

|

D

|

|

|

|

|

|

|

|

|

E

|

|

|

|

|

|

|

|

|

F

|

|

|

|

|

|

|

|

|

G

|

|

|

|

|

|

|

|

|

H

|

|

|

|

|

|

|

|

|

I

|

|

|

|

|

|

|

|

|

J

|

|

|

|

|

|

|

|

Problems on Scheduling

Q 15: A single machine work center has five jobs assigned to it. They are labeled, in the order of their arrival in the shop, as jobs A, B, C, D and E. The work center may work on only one job at a time and must complete any job it starts before starting another job. Job A has a processing time of 6 days and is due to the customer in 9 days. Job B has a processing time of 2 days and is due in 16 days. Job C has a processing time of 4 days and is due in 10 days. Job D has a processing time of 3 days and is due in 7 days. Job E has a processing time of 5 days and is due in 12 days. Using the first-come-first-served priority rule, what is the number of late (tardy) jobs?

|

Job

|

Time

|

Due Date

|

Completion Time

|

Tardiness

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q 16: A single machine work center has five jobs assigned to it. They are labeled, in the order of their arrival in the shop, as jobs A, B, C, D and E. The work center may work on only one job at a time and must complete any job it starts before starting another job. Job A has a processing time of 6 days and is due to the customer in 9 days. Job B has a processing time of 2 days and is due in 16 days. Job C has a processing time of 4 days and is due in 10 days. Job D has a processing time of 3 days and is due in 7 days. Job E has a processing time of 5 days and is due in 12 days. Using the shortest (earliest) due date rule, what is the average completion (flow) time of all jobs?

|

Job

|

Time

|

Due Date

|

Completion Time

|

Tardiness

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q 17: A single machine work center has five jobs assigned to it. They are labeled, in the order of their arrival in the shop, as jobs A, B, C, D and E. The work center may work on only one job at a time and must complete any job it starts before starting another job. Job A has a processing time of 6 days and is due to the customer in 9 days. Job B has a processing time of 2 days and is due in 16 days. Job C has a processing time of 4 days and is due in 10 days. Job D has a processing time of 3 days and is due in 7 days. Job E has a processing time of 5 days and is due in 12 days. Using the shortest processing (operating)) time priority rule, what will be the average tardiness of these orders?

|

Job

|

Time

|

Due Date

|

Completion Time

|

Tardiness

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q 18: A single machine work center has five jobs assigned to it. They are labeled, in the order of their arrival in the shop, as jobs A, B, C, D and E. The work center may work on only one job at a time and must complete any job it starts before starting another job. Job A has a processing time of 6 days and is due to the customer in 9 days. Job B has a processing time of 2 days and is due in 16 days. Job C has a processing time of 4 days and is due in 10 days. Job D has a processing time of 3 days and is due in 7 days. Job E has a processing time of 5 days and is due in 12 days. Using the shortest processing (operating)) time priority rule, what will be the average number of jobs in the system?

|

Job

|

Time

|

Due Date

|

Completion Time

|

Tardiness

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q 19: A machine shop has two machines, M1 and M2. Four jobs A, B, C, and D need to be processed through machines M1 first and M2 second. Job A will take one hour on machine M1 and three hours on machine M2. Job B will take three hours on M1 and two hours on M2. Job C, takes seven hours on M1and three hours on M2. Job D, requires five hours on M1 and one hour on M2. Using Johnson's rule, in what order should these jobs be done?

Q 20: Consider the following data for a five-job, 2-machine, flow-shop problem. Find the value of make-span (minimum time to complete all jobs) using the sequence ABCDE.

|

|

Time

|

|

Job

|

M1

|

M2

|

|

A

|

1

|

2

|

|

B

|

4

|

2

|

|

C

|

1

|

3

|

|

D

|

5

|

4

|

|

E

|

3

|

5

|

You may use the following Gantt Chart template.