Discuss the below in detail:

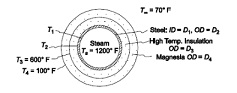

Q: A standard 4 in. steel pipe (ID = 4.026 in., OD = 4.500 in.) carries superheated steam at 1200°F in an enclosed space where a fire hazard exists, limiting the outer surface temperature to 100°F. In order to minimize the insulation cost, two materials are to be used; first a high temperature insulation (relatively expensive) applied to the pipe and then magnesia (a less expensive material) on the outside. The maximum temperature of the magnesia is to be 600°F. The following constants are known.

Steam-side coefficient ...............................h = 100 Btu/(h ft2 °F)

High-temperature insulation conductivity ........k = 0.06 Btu/(h ft °F)

Magnesia conductivity ..............................k = 0.045 Btu/(h ft °F)

Outside heat transfer coefficient....................h = 2.0 Btu/(h ft2 °F)

Steel conductivity....................................k = 25 Btu/(h ft °F)

Ambient temperature.................................Ta = 70°F

(a) Specify the thickness for each insulating material.

(b) Calculate the overall heat transfer coefficient based on the pipe OD.

(c) What fraction of the total resistance is due to (1) steam-side resistance, (2) steel pipe resistance, (3) insulation (combination of the two), and (4) outside resistance?

(d) How much heat is transferred per hour, per foot length of pipe?

GIVEN

Steam filled steel pipe with two layers of insulation

Pipe inside diameter (Di) = 4.026 in.

Pipe outside diameter (Do) = 4.500 in.

Superheated steam temperature (Ts) = 1200°F

Maximum outer surface temperature (Tso) = 100°F

Maximum temperature of the Magnesia (Tm) = 600°F

Thermal conductivities

High-temperature insulation (kh) = 0.06 Btu/(h ft °F)

Magnesia (km) = 0.045 Btu/(h ft °F)

Steel (ks) = 25 Btu/(h ft °F)

Heat transfer coefficients

Steam side ( hci ) = 100 Btu/(h ft2 °F)

Outside ( hco ) = 2.0 Btu/(h ft2 °F)

Ambient temperature (Ta) = 70°F

ASSUMPTIONS

The system is in steady state

Constant thermal conductivities

Contact resistance isnegligible