Problem1:

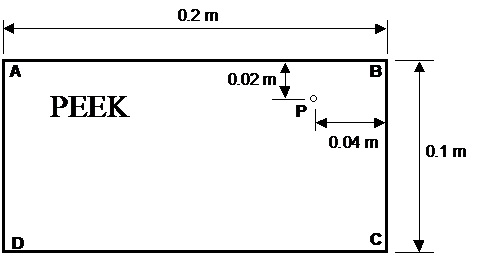

Make a computer code to simulate following solidification situation throughout a casting process:

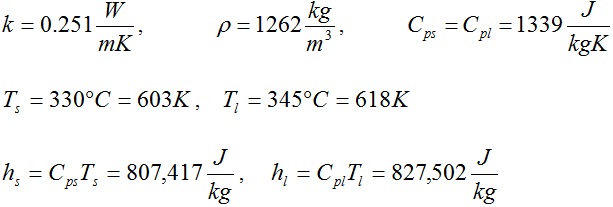

The material is a well-known polymer named as PEEK (polyetheretherketone). The properties of this material are as follows:

Suppose that Tinitial = 650 K everywhere (the pouring temperature) and that at time = 0 the wall temperatures on walls AB, BC, AD, and DC are set to Twall = 290 K (the mold temperature). Study this solidification problem numerically, and hand in following:

• A copy of your source code

• Plots of T centre versus time and Tp versus time

• The total solidification time and final point of solidification within the product.

• Contour plots of solidus and liquidus interfaces for a certain time.

• A plot showing the temporal progression of solidus interface fronts during the casting process.

Run your code several times with a deceasing mesh cell size. For each of these mesh cell sizes, report on the following:

• The total solidification time and final point of solidification within the product.

From this mesh size sensitivity analysis suggest an optimal mesh size to address this type of problem.

δ^2*T/δx^2

Δ/Δx * ΔT/Δx