Question 1

Assume that the following inventory problem fits the assumptions of the Basic Fixed-Order Quantity inventory model. If the annual demand is 12,000 units, the ordering cost is $6 per order, the holding cost is $2.50 per unit per year, which of the following is the optimal order quantity?

Select one:

a. 57,600

b. 240

c. 120.4

d. 60.56

e. None of the above

e. In case the supplier changes the design

Question 2

For this problem assume the Basic Fixed-Order Quantity inventory model fits this problem situation. Which of the following is the Total Cost (TC) of inventory given the annual demand of 35,000, setup cost of $40, a holding cost per unit per year of $2, an EOQ of 1,183 units, and a cost per unit of inventory of $20?

Select one:

a. About $1,023,456

b. About $702,366

c. About $700,002

d. Cannot be computed based on information above

Question 3

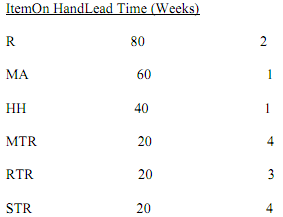

A Chic electric razor (R) is assembled from a motor assemble (MA) and a housing half (HH). The motor assembly is assembled from a housing half (HH) and a motor (MTR). The motor is assembled from a rotor (RTR) and a stator (STR). The following inventory information is provided:

If a gross requirement for 200 electric razors (R) exists in week 16 and the quantities given above are in stock (On Hand), what is the net requirement for R?

Select one:

a. 40

b. 60

c. 80

d. 120

e. None of the above

Question 4

Rather than try to adjust the master production schedule to change resource loads, it is more practical to control the flow at each bottleneck to bring capacities in line.

Select one:

a. True

b. False

Question 5

Using the Basic Fixed-Order Quantity inventory model Reorder Point formula, determine which of the following is the reorder point value given an average daily demand of 50 units and a lead-time of 10 days?

Select one:

a. 500

b. 150

c. 50

d. 5

e. None of the above

Question 6

Vance Armstrong is making his monthly order (every 30 days) for a supply of racing tires for the Sunshine Bicycle Shop. The order will take two days to arrive. Vance sells tires at an average rate of five per day (six days per week) with a standard deviation of demand of one per day. He desires to have stock of racing tires at a 98 percent service probability to satisfy his customers. He currently has 35 racing tires in inventory. How many should be ordered? From standard normal distribution table, z = 2.05

Question 7

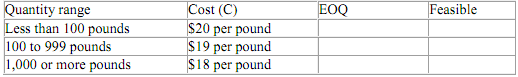

Jill's Job Shop buys Widgets for use in its production system. Each year the company uses about 10,000 Widgets that cost $10 each. The parts are needed 52 weeks/year at a constant rate. Widgets are ordered whenever remaining quantity drops to the reorder level. Holding costs amount to 20% of item cost. Every time an order is placed for more Widgets, ordering cost is $150. Lead-time to receive an order is 4 weeks. Safety stock is set at 55 units. What are the reorder quantity and the reorder point? A particular raw material is available to a company at three different prices, depending on the size of the order:

The cost to place an order is $40. Annual demand is 3,000 units. Holding (or carrying) cost is 25% of the material price. What is the economic order quantity to buy each time?

Format for Answer: The best order size is ___________ units at a cost of $____ per pound.

Question 8

The two basic categories of forecasting are qualitative and quantitative. Name some of each method and identify when you use these methods related to new products/new technology and existing products/current technology?

Question 9

Question text

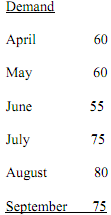

Historical demand for a product is as follows:

(a.) Using a simple four-month moving average, calculate a forecast for October.

(b.) Using single exponential smoothing with alpha=0.3 and a September forecast =70, calculate a forecast for October.

(c.) Using simple linear regression, calculate the trend line (Yt) for the historical data. The X-axis scale is: April = 1, May = 2, and so forth. Y-axis is Demand from above. Yt = a + bx =

(d.) Using the linear regression model above, what is a forecast for October?

Question 10

From the reading Decoding the DNA of the Toyota Production System, what are the components of the "DNA" that underpin TPS (and subsequently JIT and Lean)?

Question 11

Choose one of the rules of constraint/bottleneck management listed below (as demonstrated in the storyline of The Goal) and briefly discuss the concept as related to the diagram of the layout of a dentist's office shown on the diagram here.

A) Do not balance capacity, balance the flow.

B) An hour lost at a bottleneck is an hour lost for the entire system.

C) Bottlenecks govern throughput and inventory in the system.