Question 1

Frank's machine shop operates 250 days per year. Frank sells 5,000 units per year of his most popular item, a specialty gear. The set-up cost for this gear is £100 and the monthly unit cost of holding inventory is 1% of the production cost per unit, which is £50. The lead time is 10 days. When the gear is being produced, the shop can make 80 gears per day (Hint: You should use the production model for inventory management.).

Complete the following:

1. How many gears should be produced in each run and at what minimum cost?

2. What is the cycle time?

3. Find the reorder point.

4. Draw a graph to depict inventory level against time and show on it the quantities found above. Also, what is the maximum inventory level?

Question 2

For this part of the Individual Project, you need to use the POM-QM for Windows software:

1. Read Appendix IV of the Operations Management (Heizer & Render, 2011) textbook.

2. Launch the POM-QM for Windows software and from the main menu select Module, and then Materials Resource Planning.

3. Program the MRP for the Individual Project Problem below and solve it with the use of POM-QM for Windows.

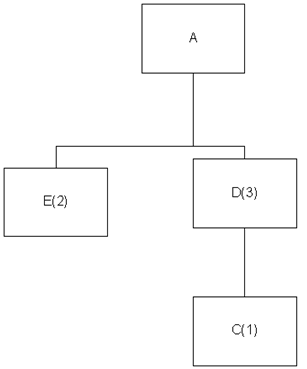

The product structure tree for the finished product A is given below.

The marketing department is estimating product A's demand to be 60 units for week 4 and 50 units for week 6. There is a scheduled receipt of 75 units for component D at the beginning of week 2. Various other MRP related information for the finished products and the components are provided below.

|

|

A

|

C

|

D

|

E

|

|

On hand

|

12

|

170

|

9

|

5

|

|

Lead time

|

2

|

2

|

1

|

1

|

|

Lot size

|

LFL

|

150+

|

multiples of 40

|

multiples of 22

|

Provide the MRP tables for all the finished products and the components for the next six weeks.