Problem 1 Facility Location

A big retail chain needs to find the best location to build new warehouse. The new warehouse will mainly serve on a weekly basis 8 stores in the northeast.

Using Euclidian distances compute the center of gravity and calculate the total transportation cost.

The following information has been collected for the 8 stores:

|

|

Rate

$/Ton Mile

|

Tons

|

Coordinates

|

|

|

|

|

x

|

y

|

|

A

|

1.30

|

300

|

700

|

1200

|

|

B

|

0.95

|

400

|

250

|

600

|

|

C

|

0.85

|

600

|

225

|

825

|

|

D

|

1.20

|

323

|

600

|

500

|

|

E

|

1.30

|

230

|

1050

|

1200

|

|

F

|

0.80

|

120

|

800

|

300

|

|

G

|

0.90

|

400

|

925

|

975

|

|

H

|

1.23

|

300

|

1000

|

1080

|

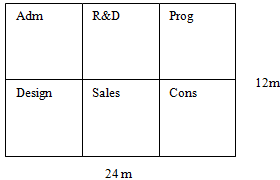

Problem 2 Facility layout

Assume the following office plan among different departments.

The average number of contacts among departments per week is indicated below:

|

|

Adm

|

R&D

|

Prog

|

Design

|

Sales

|

Cons

|

|

Adm

|

-

|

2

|

8

|

6

|

20

|

10

|

|

R&D

|

|

-

|

30

|

50

|

40

|

20

|

|

Prog

|

|

|

-

|

50

|

10

|

70

|

|

Design

|

|

|

|

-

|

20

|

30

|

|

Sales

|

|

|

|

|

-

|

50

|

|

Cons

|

|

|

|

|

|

-

|

Compute the total "load-distance" LD score for the current solution, and then try to find an improved layout.

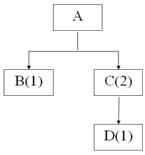

Problem 3 Materials Requirements Planning

A manufacturing plant produces an end-item A, according to the following bill of materials:

The MPS for the end-item A is given in table 1. The manufacturing / assembly lead times, the lot sizing rules, and the current on-hand inventory for all constituting items are given in table 2. There are scheduled receipts for item C at week 1 (100 pieces) and for item D at week 3 (80 pieces).

Table 1: MPS Quantities

|

MPS Quantities

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

Gross Requirements (Α)

|

-

|

30

|

-

|

50

|

-

|

200

|

-

|

120

|

180

|

60

|

Table 2: Lead times, lot sizing rules, on-hand inventory

|

Item

|

Lead Time

|

Lot sizing rule

|

On-hand inventory

|

|

A

|

2 weeks

|

Lot-for-lot

|

40

|

|

B

|

1 week

|

Fixed Order Period = 3 weeks

|

20

|

|

C

|

2 weeks

|

Lot-for-lot

|

20

|

|

D

|

3 weeks

|

Fixed Order Quantity = 500 units

|

300

|

Determine the material requirement plan (fill the following tables).

|

Item: A

|

Production Lead Time: 2 weeks

|

Lot size rule: Lot-for-Lot

|

|

Week No.

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

Gross Requirements

|

|

|

|

|

|

|

|

|

|

|

|

Adjusted Scheduled Receipts

|

|

|

|

|

|

|

|

|

|

|

|

Projected on-hand 40

|

|

|

|

|

|

|

|

|

|

|

|

Net Requirements

|

|

|

|

|

|

|

|

|

|

|

|

Planned order receipt

|

|

|

|

|

|

|

|

|

|

|

|

Planned order release

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item: B

|

Production Lead Time: 1 week

|

Lot size rule: FOP (P=3 weeks)

|

|

Week No.

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

Gross Requirements

|

|

|

|

|

|

|

|

|

|

|

|

Adjusted Scheduled Receipts

|

|

|

|

|

|

|

|

|

|

|

|

Projected on-hand 20

|

|

|

|

|

|

|

|

|

|

|

|

Net Requirements

|

|

|

|

|

|

|

|

|

|

|

|

Planned order receipt

|

|

|

|

|

|

|

|

|

|

|

|

Planned order release

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item: C

|

Production Lead Time: 2 week

|

Lot size rule: Lot-for-Lot

|

|

Week No.

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

Gross Requirements

|

|

|

|

|

|

|

|

|

|

|

|

Adjusted Scheduled Receipts

|

|

|

|

|

|

|

|

|

|

|

|

Projected on-hand 20

|

|

|

|

|

|

|

|

|

|

|

|

Net Requirements

|

|

|

|

|

|

|

|

|

|

|

|

Planned order receipt

|

|

|

|

|

|

|

|

|

|

|

|

Planned order release

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item: D

|

Production Lead Time: 3 weeks

|

Lot size rule: FOQ (Q=500)

|

|

Week No.

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

Gross Requirements

|

|

|

|

|

|

|

|

|

|

|

|

Adjusted Scheduled Receipts

|

|

|

|

|

|

|

|

|

|

|

|

Projected on-hand 300

|

|

|

|

|

|

|

|

|

|

|

|

Net Requirements

|

|

|

|

|

|

|

|

|

|

|

|

Planned order receipt

|

|

|

|

|

|

|

|

|

|

|

|

Planned order release

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|