Observing plastic deformation

The aim of this demonstration is to make some observations of the surface relief produced in commercial purity as-cast zinc after bending.

In particular, we are interested to understand how we might strengthen the material.

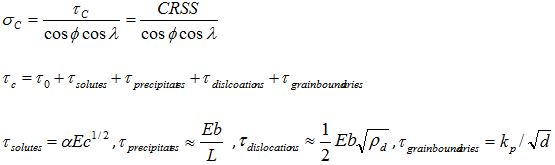

Governing equations:

From lecture:

We can assume that τ0 = 0.2 MPa, b=0.3 nm and that kp = 1 MPa.mm1/2

Questions

1. Estimate the 'Schmid Factor', which is used to convert the CRSS into a critical tensile 'yield' stress. Use the measured angle between the slip trace and the sample long axis ___________________ . Assume that the slip direction and the slip plane normal both lie in the sample observation surface.

2. Record the grain size 'seen' by the active slip system______________________.

3. Assume the above values are typical and estimate the tensile yield stress assuming that the strength contributions from solutes, precipitates and dislocations are negligible.

4. Specify the grain size you would need to increase the tensile yield strength by 50MPa.

5. Specify the inter-precipitate spacing you require to increase the tensile yield strength by 50 MPa.

6. Specify the dislocation density you would need to increase the tensile yield strength by 50 MPa. Do some research and estimate how much tensile strain this would require.

7. Look up zinc alloys in the CES database or some other database and identify two common alloying additions used in zinc. Use the data available to determine the solute strengthening contributions in MPa/wt% for each - give the data you use in a table and provide a reference.