Question 1: A firm desires to control the inventory levels so as to minimize the sum of holding and order costs. This costs the firm $20 to place an order. The firm estimates its yearly inventory carrying costs at 20%. Weekly demand is 100 units, and there are 50 weeks in the work year. The item costs $10 per unit. The EOQ is around:

A. 316

B. 224

C. 145

D. 45

E. 32

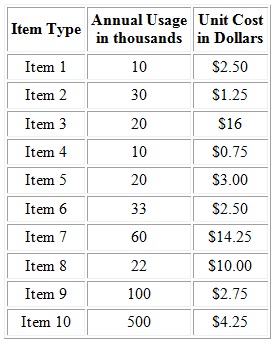

Question 2: Lincoln Machine Tool Company maintains an inventory pool comprising of 10 items. Each of such items has a unique demand pattern and might need a different type of inventory management system. The annual demand pattern and the unit cost of such items are given in the following table. Categorize the items in A, B, and C categories according to annual dollar usage.

Item 7 will be categorized as:

A. A item

B. B item

C. C item

D. None of the above

Question 3: By using the data of Question 2, Item 6 will be categorized as:

A. A item

B. B item

C. C item

D. None of above

Question 4: By using the data of Question 2, Item 8 will be categorized as:

A. A item

B. B item

C. C item

D. None of above

Question 5: One end item A needs three component parts: B, C, and D. The bill of material points that for each completed A, 3 units of B, 2 units of C, and 1 unit of D are required. Current inventory for the four items is as follows: There are 18 As, 40 Bs, 50 Cs and 35 Ds in stock. If the lead time for all items is one week and there are no scheduled receipts for any item, how many units of product A can be delivered to customers at the beginning of next week (week 2)?

A. 35

B. 31

C. 25

D. 13

E. None of above