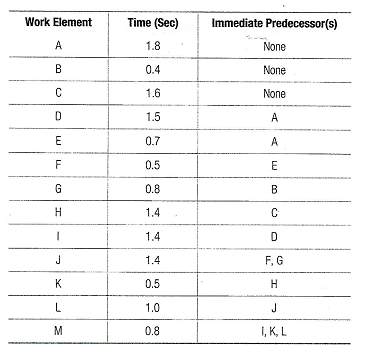

1.

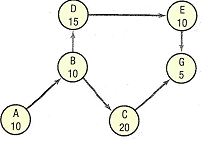

a. Draw a precedence diagram.

b. What cycle time (in minutes) results in the desired out-put rate?

c. What is the theoretical minimum number of stations?

d. Use the longest work element decision rule to balance the line and calculate the efficiency of your solution.

e. Use the most followers work element decision rule to balance the line and calculate the efficiency of your solution.

2. In order to meet holiday demand, Penny's Pie Shop requires a production line that is capable of producing 50 pecan pies per week, while operating only 40 hours per week. There are only 4 steps required to produce a single pecan pie with respective processing times of 5 min, 5 min, 45 min, and 15 min.

a. What should be the line's cycle time?

b. What is the smallest number of workstations Penny could hope for in designing the line considering this cycle time?

c. Suppose that Penny finds a solution that requires only four stations. What would be the efficiency of this line?

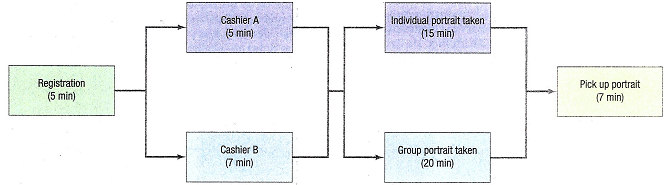

3. Melissa's Photo Studio offers both individual and group portrait options. The process flow diagram in Figure shows that all customers must first register and then pay at one of two cashiers. Then, depending on whether they want a single or group portrait they go to different rooms. Finally, everyone picks up their own finished portrait.

a. How long does it take to complete the entire process for a group portrait?

b. What single activity is the bottleneck for the entire pro-cess, assuming the process receives equal amounts of both groups and individuals?

c. What is the capacity of the bottleneck for both groups and individuals?

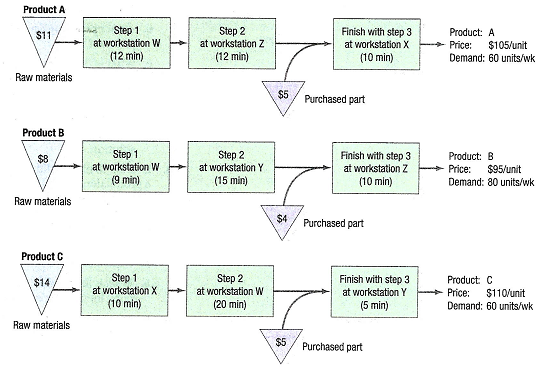

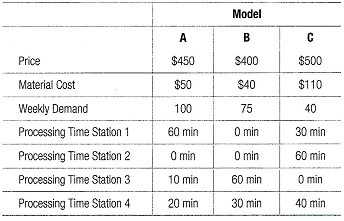

4. Yost-Perry Industries (YPI) manufactures a mix of afford¬able guitars (A, B, C) that are fabricated and assembled at four different processing stations (W, X, Y, Z). The opera¬tion is a batch process with small setup times that can be considered negligible. The product information (price, weekly demand, and processing times) and process se¬quences are shown in Figure. Raw materials and pur¬chased parts (shown as a per-unit consumption rate) are represented by inverted triangles. YPI is able to make and sell up to the limit of its demand per week with no penalties incurred for not meeting the full demand.

Each worksta¬tion is staffed by one highly skilled worker who is dedicated to work on that workstation alone and is paid $15 per hour. The plant operates one 8-hour shift per day and operates on a 5-day work week (Le., 40 hours of production per per¬son per week). Overhead costs are $9,000/week. Which of the four workstations, W, X, Y, or Z, has the highest aggre-gate workload, and thus serves as the bottleneck for YPI?

5. Yost-Perry Industries (YPI) senior management team wants to improve the profitability of the firm by accept¬ing the right set of orders. Currently, decisions are made using the traditional method, which is to accept as much of the highest contribution margin product as possible (up to the limit of its demand), followed by the next high¬est contribution margin product, and so on until all avail¬able capacity is utilized.

Because the firm cannot satisfy all the demand, the product mix must be chosen care¬fully. Jay Perry, the newly promoted production supervi¬sor, is knowledgeable about the theory of constraints and the bottleneck-based method for scheduling. He believes that profitability can indeed be improved if bottleneck resources are exploited to determine the product mix. What is the change in profits if, instead of the traditional method that YPI has used thus far, the bottleneck method a vocated by Jay is used for selecting the product mix?

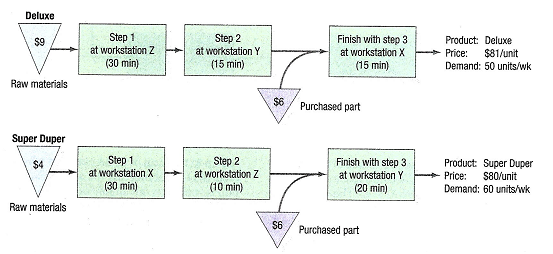

6. A'J's Wildlife Emporium manufactures two unique bird-eders (Deluxe and Super Duper) that are manufactured and assembled in up to three different workstations CX,Z) using a small batch process. Each of the products is produced according to the flowchart in Figure Additionally, the flowchart indicates each product's price, weekly demand, and processing times per unit. Batch setup times are negligible. A.J. can make and sell up to the limit of its weekly demand and there are no penalties for

not being able to meet all of the demand. Each worksta-tion is staffed by a worker who is dedicated to work on that workstation alone and is paid $16 per hour. The plant operates 40 hours per week, with no overtime. Overhead costs are $2,000 per week. Based on the information pro¬vided, as well as the information contained in the flow¬chart, answer the following questions.

a. Using the traditional method, which bases decisions solely on a product's contribution to profits and over¬head, what is the optimal product mix and what is the overall profitability?

b. Using the bottleneck-based method, what is the opti¬mal product mix and what is the overall profitability?

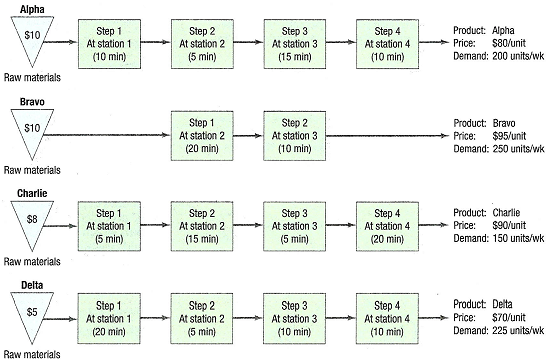

7. Cooper River Glass Works (CRGW) produces four differ¬ent models of desk lamps as shown in Figure. The operations manager knows that total monthly demand exceeds the capacity available for production. Thus, she is interested in determining the product mix which will maximize profits. Each model's price, routing, processing times, and material cost is provided in Figure. Demand next month is estimated to be 200 units of model Alpha, 250 units of model Bravo, 150 units of model Charlie, and 225 units of model Delta. CRGW op¬erates only. ne 8-hour shift per day and is scheduled to work 20 days next month (no overtime). Further, each station requires a 10 percent capacity cushion.

a. Which station is the bottleneck?

b. Using the traditional method, which bases decisions solely on a product's contribution to profits and over¬head, what is the optimal product mix and what is the overall profitability?

C. Using the bottleneck-based method, what is the opti¬mal product mix and what is the overall profitability?

8. The senior management at Davis Watercraft would like to determine if it is possible to improve firm profitability by changing their existing product mix. Currently, the product mix is determined by giving resource priority to the highest contribution margin watercraft. Davis Watercraft always has a contingent of 10 workers on hand; each worker is paid $25 per hour. Overhead costs are $35,000 per week. The plant operates 18 hours per day and 6 days per week. Labor is considered a fixed expense because workers are paid for their time regardless of their utilization. The production manager has determined that workstation I is the bottleneck. Detailed production information is provided below.

a. Using the traditional method, which bases decisions solely on a product's contribution to profits and over¬head, what is the product mix that yields the highest total profit? What is the resulting profit?

b. Using the bottleneck-based method, what is the product mix that yields the highest total profit? What is the resulting profit?

9. A paced assembly line has been devised to manufacture calculators, as the following data show

a. What is the maximum hourly output rate from this line? (Hint The line can go only as fast as its slowest workstation.)

b. What cycle time corresponds to this maximum output rate?

c. If a worker is at each station and the line operates at this maximum output rate, how much idle time is lost during each 10-hour shift?

d. that is the line's efficiency?

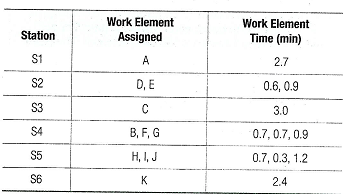

10. Jane produces custom greeting cards using six distinct work elements. She would like to produce 10 cards in each 8-hour card-making session. Figure 7.15 details each work element and its associated durations in minutes as well as their precedence relationships.

a. What cycle time is required to satisfy the required output rate?

b. What is the theoretical minimum number of worksta-tions required?

c. If lane identifies a five-station solution, what is the associated efficiency and balance delay?

d. If the cycle time increased by 100 percent, would the theoretical minimum number of workstations also in-crease by 100 percent?

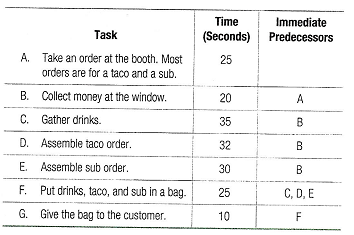

11. Greg Davis, a business major at the University of South Carolina (USC), has opened Six Points Saco (SPS), a spe¬cialty subs-taco restaurant, at the rim of the USC campus. SPS has grown in popularity over the one year that it has been in operation, and Greg is trying to perfect the busi¬ness model before making it into a franchise. He wants to maximize the productivity of his staff, as well as serve

customers well in a timely fashion. One area of concern is the drive-thru operation during the 11:30 A.M. to 12:30 P.M. lunch hour.

The process of fulfilling an order involves fulfilling the tasks listed below.

Greg is interested in getting a better understanding of the staffing patterns that will be needed in order to op¬erate his restaurant. After taking a course in operations management at the university, he knows that fulfilling a customer order at SPS is very similar to operating an assembly line. He has also used the POM for Windows software before, and Wants to apply it for examining different demand scenarios for serving his customers.

a. If all the seven tasks are handled by one employee, how many customers could be served per hour?

b. If Greg wants to process 45 customers per hour, how many employees will he need during the peak period?

c. With the number of employees determined in part b, what is the maximum number of customers who could be served every hour (i.e., what is the maximum out¬put capacity)?

d. Assuming that no task is assigned to more than one employee, what is the "maximum output capacity" from this assembly line? How many employees will be needed to actually accomplish this maximum output capacity?

e. Beyond the output accomplished in part d, if Greg decides to add one additional worker to help out with a bottleneck task, where should he add that worker? With that addition, would he be able to process more customers per hour? If so, what is the new maximum output capacity for the drive-thru?

12. Refer back to problem 1. Suppose that in addition to the usual precedence constraints, there are two zoning con-straints within the trim line. First, work elements IC and L should be assigned to the same station; both use a com¬mon component, and assigning them to the same station conserves storage space. Second, work elements H and cannot be performed at the same station.

a. Using trial and error, balance the line as best you can.

b. What is the efficiency of your solution?