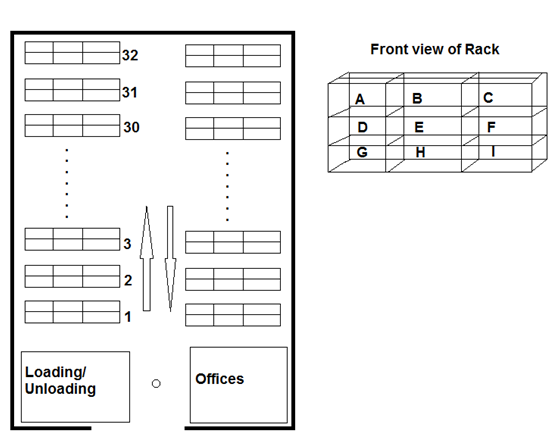

Established in Al-Khobar, Kingdom of Saudi Arabia, Logistics Solution Services (LSS) is another prime division of SAF Group of Companies. Its innovative management, sophisticated hardware, software and skilled manpower services has earned it a unique position in Saudi Arabia gaining a reputation for high quality standards in warehouse management and third party logistics. LSS is currently adding a new warehouse of more than 8,000 m2 in Dammam second industrial city. Your job in this project is to optimize the performance of this warehouse. One agreed upon measurement is to minimize the total traveled distances that items go through in and out of the warehouse. The following is a proposed layout of the facility spanning 32 aisles on both sides giving a total of 64 available aisles for storage. Each aisle is composed of 9 compartments named from A to I. Loading is done on one end while unloading is done on the other, this would allow ease of implementing a FIFO system when required for some products with expiration dates. Each compartment is 7 m length, 5 m depth, and 3 m height totaling 105 m2 in volume. Distance between aisle 1 and 2 is 4 m which is the same distance between aisle 2 and 3 and so forth. Aisle 1 is 15 m away from the loading and unloading area. Aisle 33 is symmetric to aisle 1 with respect to the forklift path.

Constraints:

- Once an item is dedicated a storage compartment then all of the items should be stored adjacently so workers would not get confused.

- Some items cannot be stored in second or third elevations due to weight restrictions.

The following data represents monthly movement of different items along with required number of compartments for storage.

|

No.

|

Name

|

Required

|

Movement

|

Weight restriction?

|

|

1

|

Qw134

|

21

|

12

|

N

|

|

2

|

Er412

|

15

|

45

|

N

|

|

3

|

Ty712

|

13

|

34

|

N

|

|

4

|

Rg966

|

17

|

62

|

N

|

|

5

|

Ds105

|

22

|

101

|

N

|

|

6

|

Vf331

|

19

|

75

|

Y

|

|

7

|

Xs655

|

12

|

18

|

Y

|

|

8

|

Za812

|

7

|

54

|

Y

|

|

9

|

Bh545

|

18

|

19

|

Y

|

|

10

|

Hj997

|

25

|

77

|

N

|

|

11

|

Hm512

|

32

|

54

|

N

|

|

12

|

Sc112

|

20

|

39

|

N

|

|

13

|

Qd422

|

31

|

72

|

N

|

|

14

|

Jy587

|

42

|

51

|

N

|

|

15

|

Vb612

|

16

|

81

|

Y

|

|

16

|

Cd222

|

14

|

120

|

Y

|

|

17

|

Op395

|

12

|

15

|

N

|

|

18

|

Ms563

|

28

|

71

|

N

|

|

19

|

Nm588

|

29

|

11

|

N

|

|

20

|

Zw101

|

11

|

29

|

N

|

Formulate the problem as a MILP and solve it to come up with the assignment that minimizes total item movement in meters.

Part2----Logistics

A logistics company wishes to expand by purchasing a number of new trucks of varying sizes and capabilities. The company has 5 Million Saudi Riyals for this project and is targeting three types of trucks, The Stake Body (SB), Heavy Semi Truck (HS) and Refrigerated Vans (RV). Demand for various products to be shipped are given on a daily basis and is assumed to continue through the year after shipping contracts have been signed. The following table contains the items with shipping rates and are given three colors namely green for items requiring the SB, yellow for HS items and red for RV items. Every truck driver can only make three trips a day maximum due to traffic regulations requiring sufficient rest. The company wishes to at least buy one type of truck to guarantee diversity and promising market share. What would be your suggestion to the company on the optimal number of each truck to purchase in order to maximize profit?

Truck Data:

|

Truck

|

SB

|

HS

|

RV

|

|

Purchase cost SR

|

199,000

|

265,000

|

312,000

|

|

Insurance cost SR

|

6,000

|

12,000

|

15,000

|

|

Registration cost SR

|

2,000

|

3,500

|

4,000

|

|

Maintenance cost SR

|

4,000

|

9,000

|

11,000

|

Demand Data:

|

Client

|

Daily trips

|

Rate SR/ trip

|

Client

|

Daily trips

|

Rate SR/ trip

|

|

Junly

|

8

|

1,200

|

Sams

|

6

|

1,500

|

|

MLK

|

14

|

950

|

Beck

|

8

|

1,100

|

|

Ual

|

8

|

1,300

|

Fly7

|

10

|

1,350

|

|

FLB

|

18

|

875

|

Port

|

20

|

700

|

|

e-home

|

14

|

900

|

Mark

|

16

|

980

|

|

SUzky

|

8

|

1,100

|

Slam

|

14

|

850

|

|

Clam

|

10

|

1,000

|

Hunt

|

10

|

1,150

|