Question 1:

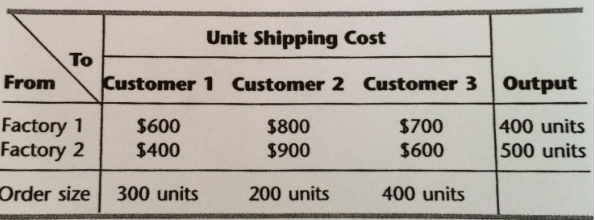

The Medequip Company produces precision medical diagnostic equipment at two factories. Three medical centres have placed orders for this month's production output. The table to the right shows what the cost would be for shipping each unit from each factory to each of these customers. Also shown are the number of units that will be produced at each factory and the number of units ordered by each customer.

A decision now needs to be made about the shipping plan for how many units to ship from each factory to each customer to minimize total shipping cost.

(a) Formulate a linear programming model for this problem.

Question 2:

The Metalco Company desires to blend a new alloy of 40 percent tin, 35 percent zinc, and 25 percent lead from several available alloys having the following properties:

|

Property

|

|

|

Alloy

|

|

|

|

1

|

2

|

3

|

4

|

|

|

Percentage of tin

|

60

|

25

|

45

|

20

|

50

|

|

Percentage of zinc

|

10

|

15

|

45

|

50

|

40

|

|

Percentage of lead

|

30

|

60

|

10

|

30

|

10

|

|

Cost (111b)

|

77

|

70

|

88

|

84

|

94

|

The objective is to determine the proportions of these alloys that should be blended to produce the new alloy at a minimum cost.

(a) Formulate a linear programming model for this problem.