Question1) The Hamlet of Pella is preparing for its annual Tulip festival. The organizing committee is grappling with the issue of determining the quantity and price of the commemorative T-shirts it plans to sell. The design has already been agreed upon and a manufacturer has agreed to supply the shirts at 4.50 dollars each. The committee has to decide whether to sell these T-shirts at 10 dollars or 15 dollars each. There is, of course, randomness in the demand for these T-Shirts. The committee predicts that at a price of 10 dollars, the demand is normally distributed with a mean of 800 and a standard deviation of 50. However, at a price of 15 dollars, the mean will drop to 650 and the standard deviation will increase to 200. Assume that there is no salvage value or shortage cost.

a) At the price of 10 dollars, determine the optimal number of T-shirts the committee should purchase.

b) What is the resulting expected profit?

c) If the committee implements the strategy with the price of 10 dollars, what percentage of customers will not be able to obtain a T-Shirt?

d) At the price of 15 dollars, determine the optimal number of T-shirts the committee should purchase.

Question2) Pete's tire shop sells both tires and rims at a fairly steady rate of 50 per week and 5 per week respectively. A typical tire costs 60 dollars and a typical rim costs 160 dollars. Pete's uses an annual holding cost rate of 25%. Assume that there are 50 weeks in a year.

a) Pete's orders its tires from Tires-R-Us which charges a fixed cost (shipping, labor, and administration) of 750 dollars per order, and its rims from Rims-R-Us which charges a fixed cost (shipping, labor, and administration) of 1250 dollars per order. What is the order size that Pete's should use if it wishes to minimize its annual cost associated with its tires?

b) What is the resulting total annual cost (holding and ordering costs)for tires?

Tires-R-Us and Rims-R-Us merged to form Wheels-R-Us and Pete's now has the ability to combine orders for tires and rims at a fixed cost of 1000 dollars per order. Pete's has decided to place an order every 10 weeks.

c) Under this policy, what is the order quantity for the tires? What is the order quantity for the rims?

d)What is the resulting annual total cost (holding and ordering costs)?

Question3) SteinMart has seven cashier stations placed strategically around their store so that each of them serves a seventh of the 100 customers that the store sees, on average, per hour. Assume that the inter-arrival times of the customers are exponentially distributed. A cashier takes an average of 3 minutes to serve a customer, but the processing time is highly random with a standard deviation of about 7.5 minutes.

a) For a typical cashier, compute the percentage of time he/she is idle.

b) What is the average number of customers waiting at each of the cashier stations?

The store manager decided to consolidate the cashiers into two locations each now having only three cashiers each (the seventh is gone). Assume that each of the two new locations receives an equal number of customers.

c) What is the utilization of each of the cashiers?

d) How many customers, on average, are waiting at each location?

Question4) HMS Bruno Bakery is building a new automated bakeryin GreenwichVillage, Manhattan. Followingarethe activities that need to be completed to get the new bakery unit built and the equipment installed.

Activity Predecessor Normalduration (weeks) Minimum possible duration(weeks) Costperweek of expediting

A - 9 6 $3,000

B A 8 5 $3,500

C A 15 10 $4,000

D B, C 7 3 $2,000

E C 10 6 $2,500

F D, E 2 1 $5,000

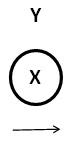

a) Draw the project diagram using AON, just show arcs, nodes, and normal durations (don’t worry about ES, EF, LS, LF).

b) Find the project duration and identify the critical path(s) (you can just type the sequence of activities for the critical path(s) here, no need to highlight it in the previous diagram).

c) If the project is not reduced by one week, a $3500 penalty will be imposed. If you could only crash one of the activities for a single week which would it be and why?

Question5) Duracell is examining its manufacturing process associated with its RB032 batteries that are commonly used in calculators. The diameter of a good RB032 battery must be no more than 2.51 cm and no less than 2.49 cm. Duracell has noticed that its production process has a mean of 2.502 with a standard deviation of 0.004 cm.

a) Under this process, what percentage, of the batteries that Duracell produces, are good?

b) What is the Cpk associated with this process?

c) If Duracell wants to move towards six-sigma capability by reducing its standard deviation, how much should it reduce it?

d) Before making the change, Duracell noticed that it is easier to move the mean than to reduce the standard deviation. How should Duracell change the mean and standard deviation of its production process to achieve six-sigma capability most easily?

Question6) Groton Upholstering Company processes, on average, 25 chairs and 8 sofas per week. The chairs are picked up about 1.5 weeks after they are dropped off, and the sofas are picked up between 4 and 10 weeks.

a) What is the average inventory of chairs?

b) If Groton Upholstering Company has in its possession 92 items on the average, calculate the average number of days that elapse before the sofas are picked up (assume 5 days per week).

c) The value of a typical chair is $550, while the value of a typical sofa is $1250. Groton Upholstering Company needs to purchase enough insurance to cover the average value of all the items in its facility. How much insurance should it buy?

d) The revenue from a chair is $550, and the revenue from a sofa is $1250. 80% of the customers use credit cards to pay their bills. What is the average accounts receivable balance if it takes 15 days for Groton Upholstering to receive the money from the credit card company (assume 5 days per week)?

Multiple Choice Questions

Select 1 Answer for Each in Bold/Underline

Question7) In EOQ and JIT strategies have any sort of relationship?

a) No, EOQ is used for ordering in large batches and JIT is for small batches.

b) No, EOQ is used for random demand, JIT is for constant demand.

c) Yes, EOQ and JIT both use z-tables to determine optimal order quantities.

d) Yes, JIT attempts to reduce setup times/costs so that EOQ is essentially 1 unit.

Question8) What determines the flow rate of a stable process?

a) The arrival rate

b) The bottle-neck capacity

c) The final step in a process

Question9) Suppose a company is introducing an entirely new product. Multiple individuals in the group have different estimates for the mean of demand for this new product. How might one use this information to best determine the details of the demand distribution?

a) Sum them up and use the totals.

b) Take the average and standard deviation of the forecasts.

c) Ignore them, come up with your own numbers based on your gut.

Question10) In class we discussed a number of equations one could use to analyze a queuing system. Given this, why might someone develop a simulation to analyze a queuing system?

a) Simulation provides more exact figures compared to the equations.

b) Simulation presents the optimal solution.

c) Simulation can provide the variability of outputs as opposed to just averages.

Question11) In the “Beer Game”, we simulated a simplified four-stage supply chain and observed the “bullwhip effect.” Who caused the bullwhip effect in your supply chain?

a) The other members of my supply chain screwed us up.

b) I admit it,my team and I were the cause.

c) Everyone screwed the darn thing up.