Automatic control and its application to the chemical process industries are very important as dynamic behavior of processes and processing equipment to be understood and analyzed properly. More advanced control systems are being introduced in process industries for enabling improvements in productivity and product quality. Prepare a brief report on following systems relevant to process control.

a-Cascade control is often used for the control of chemical reactors. With an annotated block diagram, explain the cascade control system used for a jacketed reactor.

b- Explain basic approach and methods for selecting control strategies for the application of distillation column

c-With an annotated block diagram explain application of feed-forward control system for a simple furnace system. Why the feed forward system is important when disturbance affects a process

d- Heat exchangers are very important system in a process plant. Explain dynamics and control of steam heated exchanger.

e-Chemical reactors are often the most difficult units to control in a chemical plant, but considered to be an important system. Explain briefly control of stirred reactors.

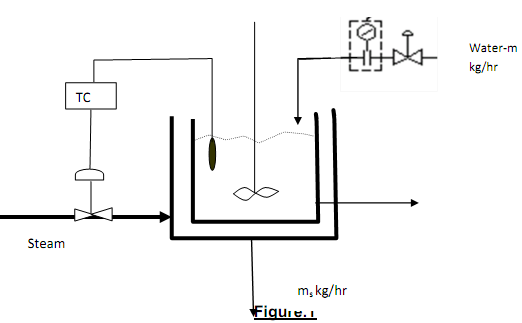

Q2 A two capacity process tank is to be analyzed using proportional and integral controllers. A process could be a steam jacketed kettle as shown in Figure.

1. Water is heated continuously by the steam flow and it is proposed to use a controller to regulate the steam flow. The steam flow is essentially depending upon to the valve opening which is controlled by TC. The temperature of the water in the kettle is measured using a RTD sensor and transmitted to the controller.

Analysis & Design aspect:

1. Assume appropriate time constants and other design parameters.

2. Study the possible step response of the system with proportional(P), and integral(I) controllers.

3. Evaluate the stability using Rouths Hurwartz criterion and obtain the range of K value for the stability under various controllers.

4. Evaluate the relative stability of the system with P and I controllers.

5. Make recommendations for the overall design with various time constant and design parameters.