Discuss the below in detail:

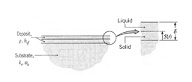

Q: Special coatings are often formed by depositing thin layers of a molten material on a solid substrate. Solidification begins at the substrate surface and proceeds until the thickness S of the solid layer becomes equal to the thickness 8 of the deposit

(a) Consider conditions for which molten material at its fusion temperature Tf is deposited on a large substrate that is at an initial uniform temperature Ti. With S = 0 at t = 0, develop an expression for estimating the time td required to completely solidify the deposit if it remains at Tf throughout the solidification process. Express your result in terms of the substrate thermal conductivity and thermal diffusivity (ks, as), the density and latent heat of fusion of the deposit (p, h,t), the deposit thickness 8, and the relevant temperatures (Tf, Ti).

(b) The plasma spray deposition process of Problem 5.25 is used to apply a thin (8 = 2 mm) alumina coating on a thick tungsten substrate. The substrate has a uniform initial temperature of Ti = 300 K, and its thermal conductivity and thermal diffusivity may be approximated as k, = 120 W/m · K and a, = 4.0 X 10-5 m2 /s, respectively. The density and latent heat of fusion of the alumina are p = 3970 kg/m3 and h, t = 3577 kJ/kg, respectively, and the alumina solidifies at its fusion temperature (Tf = 2318 K). Assuming that the molten layer is instantaneously deposited on the substrate, estimate the time required for the deposit to solidify.