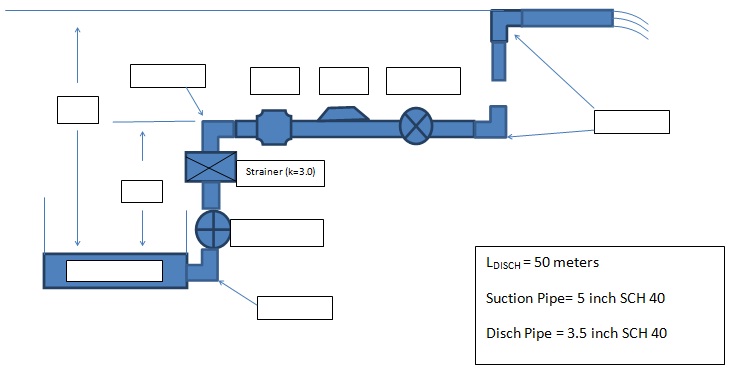

Question 1: As shown in the sketch, water at 20° C is being pumped from a lower tank and discharged into the atmosphere 10 meters above the level of the tank. The flow rate is 1200 liters/minute. There is a negligible amount of 5 inch schedule 40 commercial steel pipe between the tank and the pump containing a square edged entrance, a ball check valve, two standard elbows and a strainer with a loss coefficient, K, of 3.0. The pump suction is three (3) meters above the level of the tank. The discharge pipe is 50 meters of 3.5 inch schedule 40 commercial steel pipe, containing a globe valve, a straight flow tee and two standard elbows.

a) Calculate the head provided by the pump (m).

b) Calculate the brake power required if the pump efficiency is 75% (kW).

c) Calculate the net positive suction head available (NPSHA) if the atmospheric pressure is 100 kPa. (m)

Question 2: You Already calculated one point of HA at various flow rates for the system curve. Develop the system curve by calculating HA at various flow rates for the system given, and plot the values on attached Pump Characteristic Curve and determine:

a) The flow rate (1min), head (m), and BHP (kw) at which this pump will operate in the system.

b) With the pump curves given, develop an efficiency curve for the pump and determine the maximum efficiency and the efficiency at which the pump system will operate.

Data givenand pulled from tables/charts:

Water @ 20oC Q = 1200 liters/min = .02 m3/s

γ= 9.79 kN/m3Z1 = 10m

ρ= 998 kg/m3Z2 = 3m

n = 1.02 X 10-3

ν = 1.02 X 10-6

Pipe between Tank and Pump (negligible):

5 in commercial steel (40)

D = .4206 ft

= 128.2mm = .1282m

A = 0.1390 ft2

= 1.291 X 10-2 m2

Discharge pipe = 50 meters

3.5 in commercial steel (40)

D = .2957ft

= 90.1 mm = .0901m

A = 0.068 ft2

= 6.381 X 10-3 m2

Ball Check Valve, Le/D = 150

Standard Elbow. Le/D = 30

Strainer, K = 3.0

Global Valve, Le/D = 340

Straight flow Tee, Le/D = 60