Assignment:

Problem 1. You are hardening a steel surface by carburization at 1,000 °C using a hydrocarbon gas. (a) Suppose you know that the carbon concentration drops from 5 at.% at 1 mm depth to 4 at.% at 2 mm depth. Estimate the flux of C atoms in this region. (b) Next, suppose that you are given that the hydrocarbon gas establishes a surface concentration of Cs = 1.0 wt.% C and that the initial, uniform composition of your metal is C0 = 0.2 wt.% C. How long will it take your steel to reach a composition 0.6 wt.% C at a depth of 1 mm? Data: ρFe = 7.63 g/cm3 at 1,000 °C, D0 = 2.0 × 10-5 m2/s, Q = 142 kJ/mol. Hint: You will need a way to calculate erf-1(z), i.e., a table or calculator.

Problem 2. You have the following materials available for manufacturing a spherical pressure vessel:

|

Alloy

|

[MPa]

|

P[g/cm3]

|

Price[$/kg]

|

|

1040 plain-carbon steel

|

600

|

7.80

|

0.63

|

|

304 stainless steel

|

205

|

7.80

|

3.70

|

|

3003-H14 aluminium

|

145

|

2.73

|

3.00

|

|

Ti-5AI-2.5s

|

827

|

4.46

|

15.00

|

If the stress σ in the (thin) wall of spherical vessel pressurized to pressure p is given by

ó= PR/ 2t

where t is the thickness of the vessel wall and R is its radius. Calculate the mass of a vessel constructed so that the stress in the wall is less than the yield stress, including a safety factor of Which material gives the lightest vessel? Which material gives the cheapest? Hint: for a thinwalled pressure vessel in which t is small, t2 and t3 are ≈ 0.

Problem 3. The function

cA(x,t) = b/ √πDAt exp [-x2/4DAt]

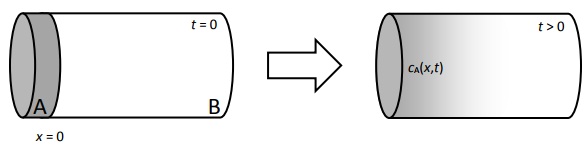

describes the concentration c (in atom fraction) after diffusion of A in a cylinder of material B which has had a disk of material A welded to one of its ends (see diagram). At what depth x in the cylinder of B does the concentration of A reach 0.1% after time t = 1,000 s at 1,000 K? Data:

D0 = 10-10 m2/s, b = 10,000 m, and Q = 20,000 J/mol.

Problem 4. The critical shear stress for dislocation motion τc is a physical parameter that depends on a number of different structural variables, such as the dislocation density ρ.

This relationship is sometimes summarized as τc(ρ) = τ0 + A√ρ ,

where τ0 and A are constants. From experiments performed on copper, τc = 0.69 MPa for ρ = 104 mm-2 and τc = 2.0 MPa for ρ = 105 mm-2. What is the yield stress σy of single crystal of copper when ρ = 106 mm-2 and the crystal is loaded along an axis that makes an angle of φ = 65° with the slip plane? (Take the slip direction angle to be λ = 45°.)

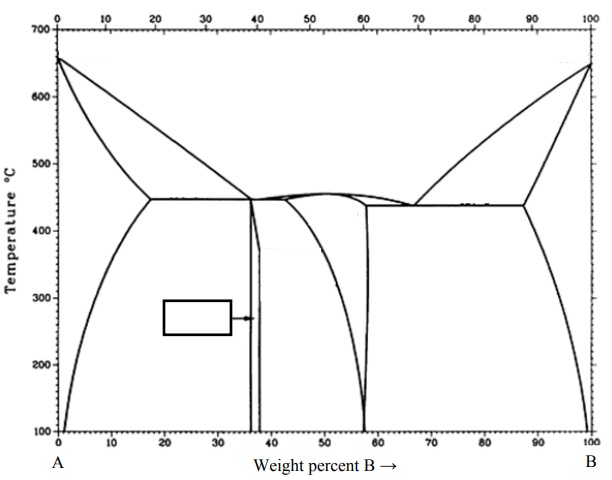

Problem 5. Label the various phases in this phase diagram (L, α, β, etc.)

Problem 6. A sample of brass was deformed in a tensile test, producing the following data. The initial length of the specimen was l0 = 35 mm and the initial area was A0 = 10.5 mm2. What are the (a) elastic modulus, (b) the 0.2% offset yield stress, and (c) the ultimate tensile stress. What are the true stress and true strain at the point of highest load? Making a plot of these data could help.

Load [N] Extension[mm]

0 0.0000

66 0.0112

177 0.0157

327 0.0199

462 0.0240

797 1.72

1350 5.55

1720 8.15

2220 13.07

2690 22.77

2410 25.25

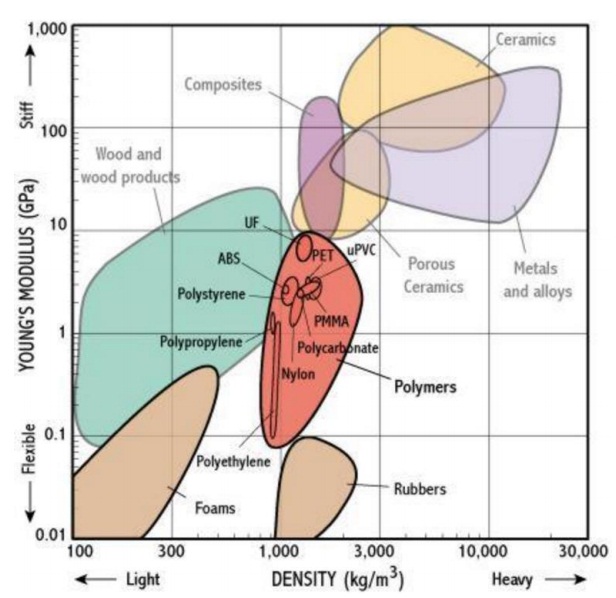

Problem 7. Suppose that you are designing a component that has a volume of 50 cm3. If the total mass of the component is to be no more than 60 g and the elastic modulus must be at least 2.0 GPa, what polymers can be used to fabricate the part?