Question 1: Describe the construction of different kinds of power transformer?

Explain with the help of diagrams the given in relation to the construction of power transformers. Include the merits and demerits in your explanation.

a) Core type.

b) Shell type.

c) Sandwich wound.

d) Concentric wound.

Question 2: Recognize the operating principles of a power transformer under no-load and load conditions: A 230/1000V 50 Hz, single phase transformer has the given test data:

Open circuit test (L.V.)

Primary voltage = 230V

Primary current = 1.30 A

Input power = 115W

Short circuit test (H.V.)

Primary voltage = 50 V

Secondary current = 5.55A

Input power = 165 W

a) Find out and sketch the equivalent circuit for the transformer?

b) Find out the efficiency of the transformer at full load current at a power factor of unity and 0.8 lagging?

c) Find out the percentage regulation at a power factor of unity and 0.8 lagging?

Question 3: Discuss the modes of connection for polyphase transformers?

Discuss with help of electrical grouping and wiring connection diagrams the various kinds of connections for polyphase transformers listed below:

a) Dd 6

b) Dz 0

c) Yd 1

d) Yz 11

Question 4: Discuss the factors governing the tariff structures?

Describe three various industrial tariff structures; include details of the type of business which would suit each tariff structure.

Question 5: Analyze the methods for reducing energy consumption? Find out the cost of energy used in a system?

The energy consumption for a small factory is given at the end of the brief.

a) Three commercial tariffs from an energy supplier are shown below. Using these (or other commercially available tariffs), determine the most suitable tariff for the factory detailed. Your answer must be supported by mathematical analysis.

Tariff A:

Standing charge per quarter of £21.95 and every unit is charged at 19.93 ppu

Maximum demand is charged at £6.95 per KVA per annum

Tariff B:

All units are charged at 25.70 ppu

Maximum demand is charged at £5.95 per KVA per annum

Tariff C:

First 1500 units in a quarter is charged at 21.82 ppu

All additional units in the quarter charged at 18.49 ppu

Maximum demand is charged at £7.45 per KVA per annum

b) Propose changes to the working practices of the factory detailed in order to reduce the energy consumption and the cost of the energy bill.

Additional Information:

Factory Details:

The factory is fed and metered at 400/230V three-phase and neutral. It comprises of a main factory area, a storage warehouse for incoming raw materials and final products awaiting delivery and a small office block. The major intake position is located at one end of the factory and sub-main feeds are taken to the warehouse and office block.

The factory is on one level with big open doors at one end where goods and materials are moved to and from the warehouse. This is constructed of brick walls with a high single pitched roof and few windows.

The warehouse is a tall building of similar construction to the factory with two roller shutter doors, one for deliveries of raw materials and one for distribution of the finished product.

The office block is a brick building with a flat timber and felt roof. This has recently been refurbished. New double glazed windows were fitted and the electrical supplies and the lighting scheme were brought up to modern standards.

Electrical Loads:

1 x three-phase 45kW electrode boiler for heating a large volume of water to a temperature of 95oC for product washing; the water is then flushed down to the sewerage system

1 x three-phase 22kW processing unit operating with a total power factor of 0.71 lagging.

7 x three-phase 9kW pump motors operating at 0.82 power factor lagging.

12 x single-phase 2.25kW motors, various uses, operating at 0.78 power factor lagging.

16 x single-phase 3kW wall mounted forced convector heaters operating at 0.92 power factor lagging.

9kW of fluorescent discharge lighting operating at 0.76 power factor lagging employing magnetic choke switch start circuits fitted with standard discharge tubes.

Warehouse:

5kW of high bay high pressure mercury vapor lighting operating at 0.75 power factor lagging.

7 x 3kW block storage heaters.

Office:

8kW of single-phase power feeding computer equipment and vending machines.

3 x 2.25kW storage heaters

2.5kW of high frequency electronic ballast fluorescent lighting operating at 0.97 power factor lagging.

Energy Consumption Profile:

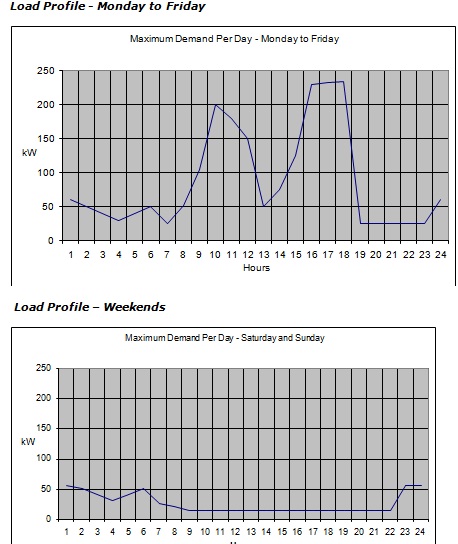

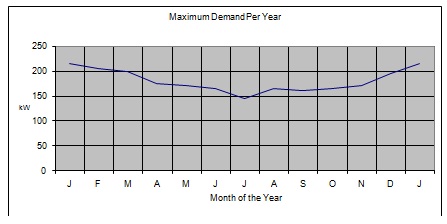

The three graphs shown point out the load pattern for the whole factory complex. The load profile for Monday to Friday and Saturday and Sunday can be supposed to be reasonably constant all through the year. Seasonal changes can be recognized by using the third graph as this shows the loading based on a weekly maximum demand.

This can be taken that the initial cost of static, loss-free capacitors, comprising that of the essential control gear is £65.00 per kVAr. The annual interest and depreciation charges total 12% per annum.

The total number of units consumed throughout the 12 month period 2011 was 384,125.