Assignment:

Facility Design Engieering:

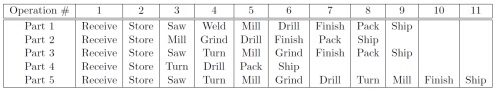

A local manufacturing company is in the process of planning a new plant. The company has identified five "vital few" part types to be manufactured in this plant after a Pareto analysis. The following table shows the process routings of the five part types.

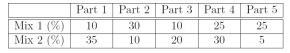

The demands for these parts are uncertain at this time, but the company expects total sales of 10,000 parts. In addition, the following two product mixes are highly likely.

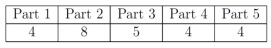

Fork trucks will be used to move materials between processes (or departments). All materials will be palletized before being loaded onto a truck, and depalletized after unloaded from the truck. A truck can carry only one loaded pallet at a time, but can carry up to five empty pallets. The number of parts per pallet will be as follows. Empty pallets are returned to the receiving area after parts are shipped.

Task

Analyze the given information and submit a report that summarizes the results of your analysis including a from-to chart, activity relationship chart and activity relationship diagram for each product mix.

Comment on the influence of product mix on the flow and activity relationships.