Applications of Pneumatics and Hydraulics - Fluid Power Diagrams

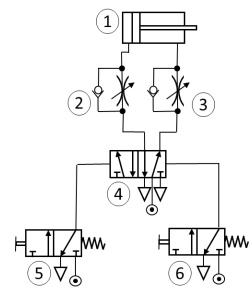

Problem 1: Figure 1 shows a pneumatic circuit diagram used to control the operation of a double acting cylinder.

(a) Name all the numbered components in the system.

(b) State how the system works, explaining the function of each component.

(c) Using a suitable diagram, show how the system could be modified so that, on a single command by the operator, the piston moves to the right and then immediately back to the left again, stopping after one such cycle.

Problem 2: Design and draw a circuit using the cascade system to operate two cylinders (A and B) which, on the operation of a start valve, produces the sequence A + B - B + A-. The cylinders should park in the positions B + A - when the start switch is in the 'off' position.

Problem 3: Modify the circuit designed for question 3 to provide an emergency stop which will park both cylinders in the extended position (i.e. A + B +).

Problem 4: Show, with the aid of a schematic diagram, how an electronic controller could be included in the circuit designed for question 3 to control the sequence of cylinder operation. The circuit should also include a fail-safe which should:

(a) act in the event of a reduced pressure at inlet to the group selecting valve

(b) act in the event of a failure of the electric supply and

(c) park the cylinders in the retracted position. Explain the operation of the fail-safe.

Problem 5:

(a) Draw the circuit diagram showing how a bi-directional hydraulic motor can be driven by a unidirectional hydraulic pump with both torque control and "meter out" speed control.

(b) Explain the operation of the circuit you have designed in part (a) above.

Applications of Pneumatics And Hydraulics - Fluid Power Diagrams

Problem 1:

(a) Draw a pV diagram to illustrate the operation of a two-stage compressor with intercooling.

(b) List the advantages to be gained by the use of a multi-stage design compressor.

Problem 2:

(a) A mass of 400 kg is to be raised by the actuation of two identical hydraulic cylinders with a piston diameter of 120 mm. Calculate the required system pressure to just raise the load.

(b) If the load is to be raised 600 mm in 10 seconds, what will be the required flowrate (Q) in litres per minute?

Problem 3: Describe the operation of a variable displacement axial piston (swash plate) pump, indicating the means by which its output is varied.

Problem 4: An item of plant 2 m3 min-1 of pulsation-free and oil-free compressed air supplied at a pressure of 7 bar. Select and size a suitable type of machine with regard to output FAD (free air delivered) and quality of air supply.

Problem 5: Using the nomogram and charts (FIGURES 1 and 2) on pages 4 and 5, determine the diameter of a suitable air main for the distribution of 6 m3 min-1 FAD. System pressure is 6 bar, the length of the pipe run is 175 metres, and a maximum pressure drop of 0.3 bar is allowed.

The distribution main must also include the following:

- 4 bends (r = 2d)

- 2 elbow fittings

- 6 tee connectors

- 2 diaphragm valves.

Problem 6: A compressor delivers 300 litres per second of free air into a pipe at a pressure of 6 bar gauge. Using the pressure drop formula:

Pressure drop = 800lQ2/RD5.31

Calculate the minimum diameter of pipe if the pressure drop in a system is to be limited to 0.3 bar when is delivered through a pipe of equivalent length 160 m .

Problem 7: List four possible causes of overheating on a multi-stage reciprocating compressor.

Problem 8: State the precautions to be taken when changing the fluid in a hydraulic system from a mineral oil based hydraulic fluid to a fire resistant fluid.

Pneumatics and Hydraulics Assignment Help service is one of the best options for students to get resolved from all your academic troubles within no time.

Tags: Pneumatics and Hydraulics Assignment Help, Pneumatics and Hydraulics Homework Help, Pneumatics and Hydraulics Coursework, Pneumatics and Hydraulics Solved Assignments, Fluid Power Assignment Help, Fluid Power Homework Help