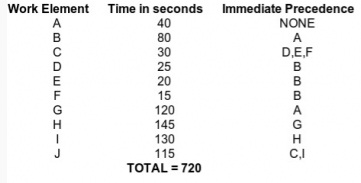

Question: You understand that it is imperative to identify and manage bottlenecks in all types of processes, relate the capacity and performance measures of one process to another, and use that information to determine the firm's best service solution. Your company is setting up an assembly line to produce 192 units of bottles per 8-hour shift. The following table identifies the relevant data:

Using a precedence diagram illustrate a possible solution for the assembly line. You are also required to discuss the desired cycle time (in seconds), the theoretical minimum number of stations, any balance delays and the efficiency of your proposed solution.